Learning to Make Hard Cheeses

My wife recently attended a class on making hard cheeses at The Ploughshare. Below is her report on the class:

After having made soft cheeses at home I was ready to forge ahead and learn to make hard cheeses, so this past Saturday I took a class. Rebekah (one of the instructors) began our class with a very informative and thorough discussion on how milk becomes cheese that even included a brief chemistry/biology lesson on pH levels and bacteria. She then demonstrated making two types of cheese starter culture—Mesophilic and Thermophilic. She moved smoothly through each step, describing the varieties and types of cheeses, the cultures and the different processes used to make cheese. She shared stories from her own experiences along with examples of what to do and what not to do.

We made six types of cheeses in the class: Chipotle Cheddar, Caraway Gouda, Parmesan, Colby, Pepper Jack and Monterey Jack.

Altogether eight people took the class. A mother and son made Pepper Jack together, another team made Parmesan, and everyone else picked one type to make themselves. I chose the Caraway Gouda. We donned our aprons and with our recipe book in hand, took our places at the stoves. As the gallons of milk heated up in gleaming stainless steel stock pots, we chatted and peeked into each other’s pots to see how our cheeses were coming along. Rebekah and Robin bustled about us, answering questions, checking our progress, feeling the curds and giving help wherever it was needed. Although the step–by–step instructions in the recipes were easy to follow, it was reassuring to have such knowledgeable instructors nearby the first time we made these cheeses.

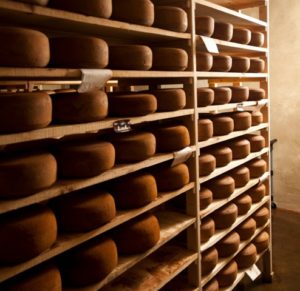

By lunchtime, the milk had turned into curds and whey. We packed the curds into molds, placed them under the wooden cheese presses, added weights to the levers and waited 30 minutes. Then we pulled the cheese out of the molds, flipped it, repacked it in the molds and pressed it again for 30 minutes. We repeated this step several more times, and the curds solidified more and more into a beautiful round of cheese. Since the cheese needs to age for two months, we left them with Rebekah and Robin. But we all took home five wedges of the various cheeses that a previous class had made. In about two months, another hard cheese class will reap the results of our efforts.

We left at the end of the day with our cheese-making manual, a bag of delicious cheeses and the inspiration and confidence to make hard cheeses at home. With broad smiles, Rebekah and Robin encouraged us with, “Call us if you need any help!”

An underground cave for aging cheese is the dream of most cheese makers. And so it was for us at

An underground cave for aging cheese is the dream of most cheese makers. And so it was for us at